Hot/Cool Thermal Cycling (Weldless Molding) Machines

Quicker molding, better looking

Kaken Geneqs' hot/cool thermal cycling (weldless molding) machine is a hybrid injection molding system that delivers both gas assist and heat-and-cool molding capabilities in one convenient package. It is a multi-functional piece of injection support equipment that delivers gas injection molding, gas press molding, and heat-and-cool molding, as well as any combination thereof. (Other equipment available by request: dedicated heat-and-cool, pressurized water, and rapid heating/cooling mold equipment.) The system accommodates a variety of needs from customers including product quality improvement, lower cost of molding, and novelty in design.

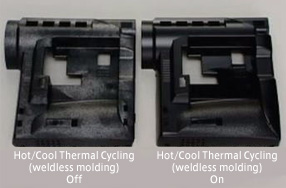

What is hot/cool thermal cycling (weldless molding) ?

Heat-and-cool molding is characterized by rapid heating of the mold, prior to the injection of the resin, to a temperature above the heat distortion temperature of the resin. Injection to the preheated mold drastically improves the flow properties of the resin, resulting in the creation of high surface quality products with almost unidentifiably faint weld lines. In the subsequent cooling stage, the mold is cooled rapidly to a temperature below the thermal distortion temperature. The precipitate solidification has the effect of eliminating weld lines and flow marks, and also offers such merits as reduction of warps and sinks, shortening of cycle time, and elimination of dimensional errors.

Hot/Cool Thermal Cycling (Weldless Molding) Machine Features

- Integration of heat-and-cool mechanism (weldless molding) and gas assist mechanism (capable of gas injection and gas press molding)

- Rapid heating by means of our one-of-a-kind steam pressure-maintenance mechanism

- Precipitate cooling using a cooling pump

- High-pressure, power-saving gas booster

- Simple mold replacement enables single-function usage (gas injection or gas press molding)

- Heat-and-cool molding can be performed independently

- Combined use of molding methods results in the synergistic effects detailed below.

Effects gained through combined use with hot/cool thermal cycling (weldless molding) machines

Gas injection molding

- Reduction of mold cycle time (improved injection velocity/shorter cooling time)

- Improved appearance

- Larger void ratio

- No need for a waste cavity

- Improved uniformity of wall thickness

Gas press molding

- Improved surface gloss grain transferability

- Thinner walls (lower thickness limit removed)

- Reduced molding cycle time

- Improved mold release characteristics

- Prevention of uneven transfer in thin-walled areas

- Walling and ribs can be eliminated with skillful design; holes can be accommodated in the design

Examples of combined uses: hot/cool thermal cycling (weldless molding) machines and gas press molding

Case 1

Case 2

Case 3