Gas Injection (gas assist molding) Machines

Kaken Geneqs has the largest installation base in Japan

Backed by Kaken Geneqs' years of experience and achievements, its one-of-a-kind gas injection machines represent an innovation in gas injection (gas assist molding) systems.

All basic technologies used in the system — from the N2 gas generator and the ultra-high pressure gas booster to the controller — were developed in-house at Kaken Geneqs. The compact system configuration helps offer user-friendliness at affordable prices, and the one-of-a-kind booster realizes impressive savings in power consumption and maintenance costs. The system can accommodate a variety of customer needs including product quality improvement, lower cost of molding, and novelty in design.

What is gas injection (gas assist molding)?

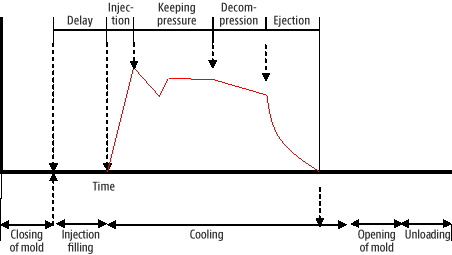

Gas assist molding is a plastic molding process characterized by injection of high-pressure nitrogen gas in the resin pressure-keeping step to maintain a constant internal pressure, enabling the reduction of such defects as sinks, warps and deformations in the finished products. It also provides a way to produce products with thinner walls and reduced weight far beyond the scope of conventional molding methods. These merits allow introduction of novel designs and structures, giving rise to significant economic benefits.

Mechanism of gas injection (gas assist molding) machines

System principle

Gas injection steps

System configuration

Applications and utilities of gas injection (gas assist molding) machines

- Best suited for large moldings (automobiles, major appliances, etc.) and precision molding machines (OA equipment, etc.)

- Can support complicated and difficult moldings

- Low mold-clamping pressure can be used even in a large-scale molding, leading to cost reduction

- Hollowed thick-walled moldings help shorten molding cycle

- Thinning of walls and trimming of weight without compromising rigidity

- Near elimination of sink, warpage, and internal distortion guarantees improved dimensional precision and high-quality products

- Greater freedom of product design

Gas Injection (Gas Assist Molding) Machine Features

Capable of 28 MPa

Kaken Geneqs' gas injection (gas assist molding) machines features 2-stage compression and a double-acting water-cooling booster. It enables gas injection at a very high pressure (max. 28 MPa), and allows a wide range of gas molding using programmable timer settings. Delivered in a compact package at an affordable price, it allows easy relocation and is compliant with the High Pressure Gas Safety Act.

Other customized gas injection machines (e.g. 37 MPa ultra-high pressure version) available by request.

List of features

- Impressive savings in power consumption

- Low-cost regular/on-demand maintenance (end-user maintenance possible)

- More than 200 units already in use as gas injection (gas assist molding) machines in injection molding machines

- Compact size with a small footprint

- Oil-free design enables compression of a variety of gas types

- Low noise (≦ 45 dB) and easy maintenance

- Integrates a nitrogen generator that outputs 99% purity N2 at high discharge pressure (28MPa)

- Can be synchronized with the molding machine using just three signals (automatic/semi-automatic, start injection, and mold opening complete)

- Touch panel control—gas molding parameters and other information can be saved for easy retrieval and display

- Compliant with the High Pressure Gas Safety Act (KHK tested)

We provide the following ancillary services: preparation of application forms for installation of high pressure gas, maintenance after installation, regular voluntary inspection, opening inspection, facility relocation, and technical guidance.

Gas Injection (Gas Assist Molding) Machine Main Specifications

[ All-in-one type (with an integrated controller) ]

| Type | KGM90 N-1 |

KGM90 N-2 |

KGM200 N-1 |

KGM200 N-2 |

KGM300 N-1 |

KGM300 N-2 |

KGM400 N-1 |

KGM400 N-2 |

|---|---|---|---|---|---|---|---|---|

| Compatible molding machine | Approx. 800 t | Approx. 2000 t | Multiple units controllable | |||||

| Discharge pressure (MPa) | 28 | |||||||

| Capacity (Nm3/day) | 90 | 200 | 290 | 400 | ||||

| Nitrogen generator | Built-in | Built-in | Built-in | Built-in | Built-in | Built-in | Built-in | Built-in |

| Pressure control | 1 Line | 2 Lines | 1 Line | 2 Lines | 1 Line | 2 Lines | 1 Line | 2 Lines |

| Power source | AC200V |

|||||||

[ Non-integrated controller type ]

| Type | KGM90N | KGM200N | KGM300N | KGM400N | (controller type) | (controller type) | (controller type) |

|---|---|---|---|---|---|---|---|

| Compatible molding machine | Approx. 800 t | Approx. 2000 t | Multiple units controllable | - | - | - | |

| Discharge pressure (MPa) | 28 | ||||||

| Capacity (Nm3/Day) | 90 | 200 | 290 | 400 | - | - | - |

| Nitrogen generator | Built-in | Built-in | Built-in | Built-in | - | - | - |

| Pressure control | Controlled by KST | 1 Line | 2 Lines | 6 stages | |||

| Power source | AC200V | AC100V | |||||